Development Activity

Reliant CCS submits a stunning 44 well carbon storage development in Southwest Alabama

BKV continues CCS partnership with Energy Transfer with new East Texas development

BKV expands CCS partnership with Energy Transfer to decarbonize East Texas natural gas processing facilities

BKV is building a large CCS network in East Texas that already has CO2 committed from Comstock’s Marquez and Bethel natural gas processing facilities

CarbonStorage.io is tracking the unidentified asset as Energy Transfer’s Ridge Amine Plant in Marquez, Texas for a 70,000 mt per year carbon capture project.

The partnership already includes ‘Lima Tango CCS’ where 177,000 mt of CO2 are captured and sequestered into a nearby Class II well in South Texas

Reliant CCS begins permitting process for Alabama’s largest carbon storage project

Reliant CCS has partnered with large timber owner, Rayonier, in December 2024 to lease 104,000 acres in Southwest Alabama

Rayonier has led carbon storage partnerships with 92,000 acres with ExxonMobil - making carbon storage a growth strategy

The Pine Hills Sequestration Hub plans to sequester up to 30 million tons of CO2 per year - making it a world class biomass-to-X hub for carbon credits

Shell Catalysts & Technologies and Technip Energies have signed a global alliance agreement for carbon capture delivery

Shell and Technip Energies are teaming up through a new global alliance to roll out Shell’s CANSOLV CO₂ capture technology with a goal to make carbon capture easier to scale and more affordable

Shell brings the tech; Technip Energies handles integration and project delivery—so customers get a full, end-to-end solution.

One standout project is Net Zero Teesside Power in the UK, which aims to be the world’s first gas-fired power plant with full carbon capture.

CCS partnerships have continued to grow as developers and technology licensors expand reach to drive down full project life cycle costs including:

ExxonMobil and MHI alliance

Tenaska and Svante collaboration

Oxy acquiring Carbon Engineering

Chevron and GE Vernova partnership

Galveston LNG Bunker Port partners with Loa Carbon for e-methane project

GLBP and Loa Carbon have signed a Letter of Intent for Loa to supply renewable e‑methane, which GLBP will convert into e‑LNG for marine fuel. Expected to be the first dedicated marine liquefaction terminal on the U.S. Gulf Coast, operations begin in 2028.

The site leverages captured CO₂ from nearby sources and low-cost ERCOT renewable power, enabling co-located e‑methane production and liquefaction. This lets shipowners use low-carbon fuel without modifying vessels or fueling systems.

The facility will also allow blending e‑methane with conventional LNG to meet FuelEU standards and cut well-to-wake carbon intensity.

GLBP is a joint venture by Pilot LNG and Seapath Group to develop, own and operate the first dedicated small-scale liquefied natural gas (LNG) facility on the U.S. Gulf Coast to serve the growing clean-energy marine fuels market.

GLBP is right on the Texas City Ship Channel and set up to supply LNG by fuel barge to the growing number of LNG-powered ships around the Houston-Galveston area

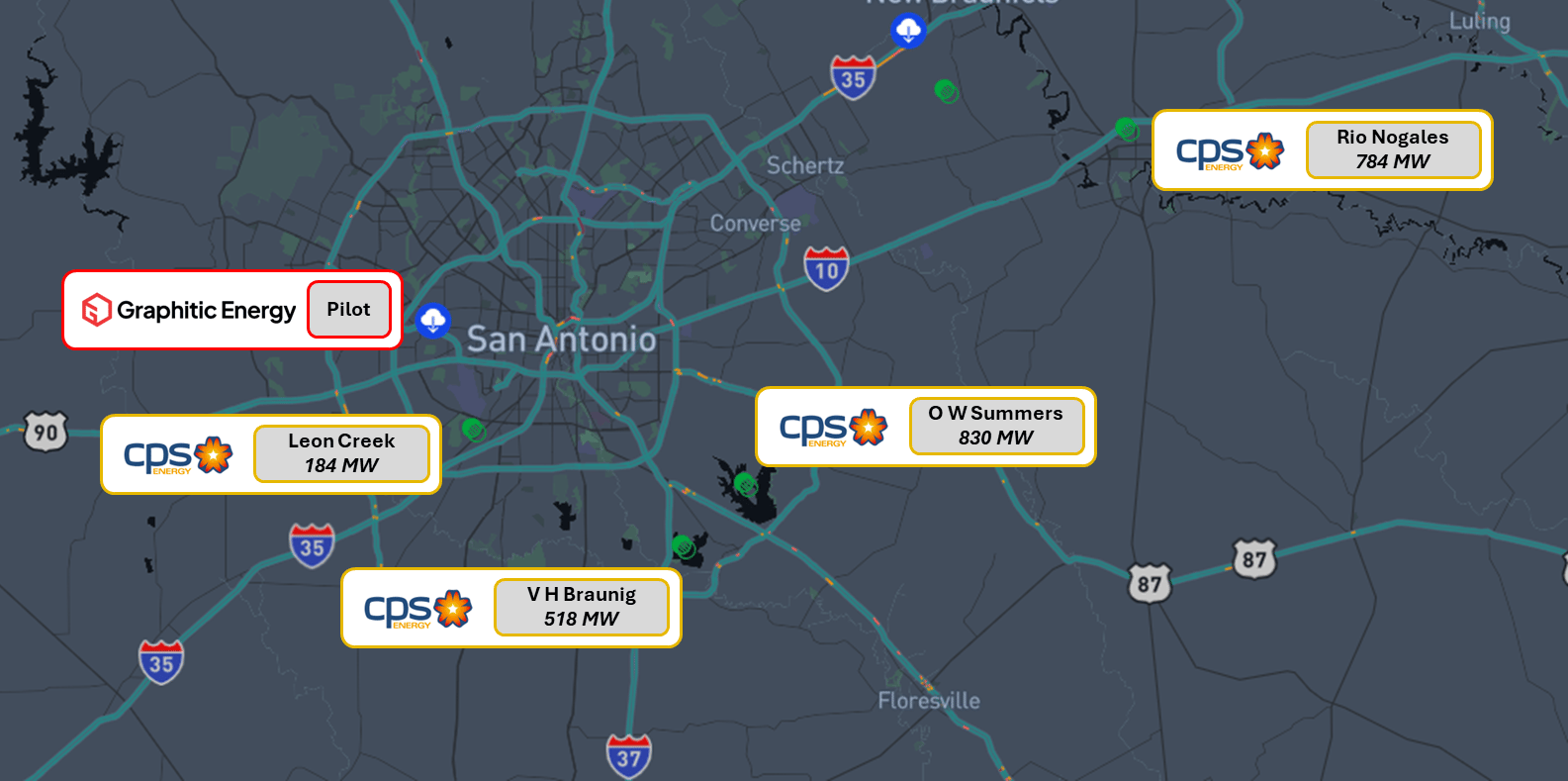

CPS Energy and Modern Hydrogen team up for San Antonio pilot project

CPS Energy and Modern Hydrogen are piloting a clean hydrogen project in San Antonio using a modular MH500 unit that produces 500 kg/day via methane pyrolysis—splitting natural gas into hydrogen and solid carbon without CO₂ emissions.

Some hydrogen powers the process itself, making it energy self-sufficient. The output can support power, fuel-cell vehicles, or blend (up to 20%) into gas systems.

Solid carbon is captured and reused, such as in asphalt. The modular setup avoids new pipelines and integrates with existing infrastructure.

CPS operates 3 natural gas power generation facilities in Greater San Antonio

Similarly, Graphitc Energy is also piloting its methane pyrolysis technology in San Antonio.

UK awards £60+ million in SAF funding

The UK government has announced £63m ($84.9m) of funding for sustainable aviation fuel (SAF) projects as part of the Department for Transport’s (DfT’s) Alternative Fuels Fund — more than half of which will go towards schemes that will produce clean hydrogen-based fuels.

Company (Project) | Description | Funding |

|---|---|---|

Alfanar Energy Ltd (Lighthouse Green Fuels) | Developing a commercial scale plant that uses torrefaction with gasification and Fischer-Tropsch synthesis technology to convert sawmill and forestry residues into SAF | £8 million |

Altalto Ltd (Altalto Immingham) | Developing a commercial scale plant that uses gasification and Fischer-Tropsch synthesis technology to convert municipal solid waste into SAF. | £3 million |

British Sugar PLC (British BioJet) | Developing a commercial scale plant that uses ethanol-to-jet technology to convert sugar beet betaine residue bioethanol into SAF. | £2.6 million |

Carbon Neutral Fuels Ltd (ASAP-DAC) | Developing a commercial scale plant that uses solid oxide electrolysis and Fischer-Tropsch synthesis technology to convert low carbon electricity and CO2 from direct air capture and biogenic sources into SAF. | £6 million |

Equilibrion Ltd (Eq.flight) | Developing a demonstration plant that uses solid oxide electrolysis, reverse water-gas shift and Fischer-Tropsch synthesis technology to convert direct air capture CO2, local heat sources and nuclear electricity into SAF. | £1 million |

Equinor Low Carbon UK Ltd (The Humber SAF Project) | Developing a commercial plant that uses methanol-to-jet technology to convert biomethanol and renewable e-methanol into SAF. | £3 million |

Essar Oil (UK) Ltd / EET Fuels (Stanlow Methanol-to-Jet) | Developing a large commercial plant that uses methanol-to-jet technology to convert renewable e-methanol and biomethanol into SAF. | £2.5 million |

ETFuels UK Ltd (Project SkyFuel Teesside) | Developing a commercial scale plant that uses methanol synthesis and methanol-to-jet technology to convert biogenic CO2 and green hydrogen into SAF. | £5 million |

LanzaJet UK Ltd (Project Speedbird) | Developing a commercial scale plant that uses ethanol-to-jet technology to convert advanced bioethanol into SAF. | £10 million |

LanzaTech UK Ltd (DRAGON 1&2) | Developing two commercial scale plants, both which use ethanol-to-jet technology. (1) One will convert recycled carbon fuel ethanol into SAF at Port Talbot. (2)Another industrial site will turn use partial reverse water-gas shift and fermentation to turn waste CO2 sources and green hydrogen into ethanol for subsequent conversion into Power-to-Liquid SAF. | £6.4 million |

NorthPointe Energy Ltd (Project Northpoint) | Developing a commercial scale plant that uses gasification and Fischer-Tropsch technology to convert refuse derived fuel into SAF. | £2 million |

OXCCU TECH Ltd (OXCCU) | Deploying a small demonstration plant that uses combined catalysis technology to convert biogenic CO2 and green hydrogen into SAF. | £3.1 million |

Power2X Solutions UK Ltd (eFuels Humber) | Developing a large commercial plant that uses methanol-to-jet technology to convert renewable e-methanol and biomethanol into SAF. | £1.5 million |

SuMo Engineering Ltd (CLEARSKIES) | BaDeveloping an end-to-end demo plant using advanced gasification, Fischer-Tropsch synthesis and gas reforming technology to convert waste to SAF. | £4.2 million |

University of Sheffield (NEXTGEN-SAF) | Demonstration plant that uses biogas-fuelled molten carbonate fuel cell technology for industrial biogenic CO2 capture, combined with renewable electrolysis, reverse water-gas shift and Fischer-Tropsch synthesis technology to produce SAF. | £1.5 million |

Willis Sustainable Fuels (UK) Ltd (Teesside Carbonshift SAF Project) | Developing a small commercial scale plant that uses autothermal reforming and Fischer-Tropsch synthesis technology to convert residue-derived biomethane into SAF. | £2.9 million |

Zero Petroleum Ltd (Fuelling Zero) | Developing a small commercial plant that uses reverse water-gas shift and novel Fischer-Tropsch synthesis technology to convert biogenic CO2 and green hydrogen into high blend SAF. | £3.5 million |

SLB Awarded Carbon Storage Contract for Northern Endurance Partnership Project in UK

UK To Integrate Carbon Removals Into ETS

45Q utilization now has price parity with geological sequestration

Sasol and INTERAC sign partnership for next generation e-SAF

Zaffra & Moeve sign MOU to develop e-SAF Facilities in Spain